- Jiangsu Pengfei Group Co., Ltd.

- Add.: Benjiaji, Northern Suburb of Hai'an City, Nantong City, Jiangsu Province, China

- Contact Person: Lemon Zhang

- Home

- Products

- Grinding Equipment

- Vertical Roller Mill

- Vertical Coal Mill

Vertical Coal Mill

The vertical coal mill offers good material compatibility, so it can be used for grinding a series of medium-hardness materials, in addition to coal. With low energy consumption and small installation space, it is an economical solution for power generation, chemical, building materials, and metallurgy industries. The machine offers reliable operation under both high and low load conditions, and its grinding system parts has long service life. Additionally, the coal mill has characteristics such as simple production flow, low noise, and large crushing ratio.

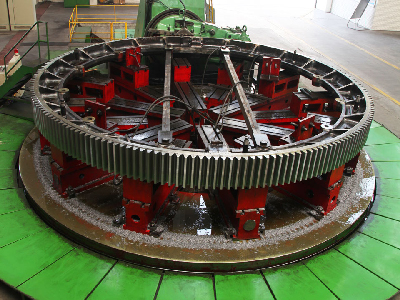

The three grinding rollers are forced to rotate, because of the high pressing force between the rollers and the rotating grinding wheel. The feeding coal material is firstly delivered on to the grinding wheel, and then is transferred to the grinding area by the centrifugal force caused by rotation.

A spring or hydraulic system is designed for pressure generation, and a statically defined three-point system is available to uniformly transfer the pressure force to the three grinding rollers. With the continuous operation of pressure-generation system, the pressing force between the grinding wheel and rollers increases constantly, thus allowing materials to be ground and sheared.

The vertical coal mill makes use of hot air for coal powder drying and delivering. Through a nozzle ring, the hot air is uniformly distributed around the grinding wheel, responsible for drying the pulverized coal and delivering the material to the separator at the upper part of the machine. After classifying in the powder separator, the qualified coal powder is discharged from the machine and collected, while the coarse materials are sent back to the grinding mill for further grinding.

Un-grindable substances in the coal material are discharged out from a port at the bottom of the machine.

The vertical coal mill primarily consists of the speed reducer, grinding roller, grinding wheel, powder separator, pressure-generation unit, positive pressure sealing system, and the steam blowing unit. Auxiliary installations such as main electric motor, lubrication oil station, hydraulic station, and sealing fan are available.

For user convenience, we can offer optional corollary equipment like the low speed transmission device, pulverized coal distributor, fast-response valve, a maintenance platform with escalator, as well as special tools for equipment installation and maintenance.

While a hydraulic pressure-generation system is adopted, the vertical mill supports pressure adjustment during operation, and can effectively prevent system damages caused by grinding of metal parts or other high hardness materials.

| Model | HRM1300M | HRM1400M | HRM1500M | HRM1700M | HRM1900M | |

| Diameter of grinding wheel | mm | Φ1300 | Φ1400 | Φ1500 | Φ1700 | Φ1900 |

| Capacity | t/h | 10-15 | 12-17 | 16-22 | 20-28 | 26-35 |

| Feeding particle size | mm | 0-40 | 0-40 | 0-45 | 0-50 | 0-55 |

| Feeding material moisture content | % | <15 | <15 | <15 | <15 | <15 |

| End product fineness (R0.08) | % | 8-12 | 8-12 | 8-12 | 8-12 | 8-12 |

| End product moisture content | % | <1 | <1 | <1 | <1 | <1 |

| Power of main electric motor | kw | 200 | 200 | 280 | 315 | 400 |

| Inlet air temperature | ℃ | <450 | <450 | <450 | <450 | <450 |

| Outlet air temperature | ℃ | 80-95 | 80-95 | 80-95 | 80-95 | 80-95 |

| Outlet airflow | m3/h | ~40000 | ~45000 | 65000 | 80000 | 100000 |

| Equipment weight | t | 45 | 52 | 75 | 96 | 100 |

Related Names

Coal Crusher | Coal Pulverizer | Coal Processing Equipment